NCR Defective Products Management

The non-conforming product management system is a digital management tool for quality management, focusing on defective product management and quick handling of defective products, helping enterprises control non-conforming products more effectively. The ITENCloud non-conforming product management system is focusing on the management of defective products from Internal on-site production line quality inspection (incoming materials, processes, shipments, etc.) , employees self-inspections or other inspecting ways, realizing the management of non-conforming products registration, NC label printing, isolation, and tracking of detecting, realizing online cross departmental collaboration for handling non-conforming products, real time tracking of processing situations and corresponding report analysis

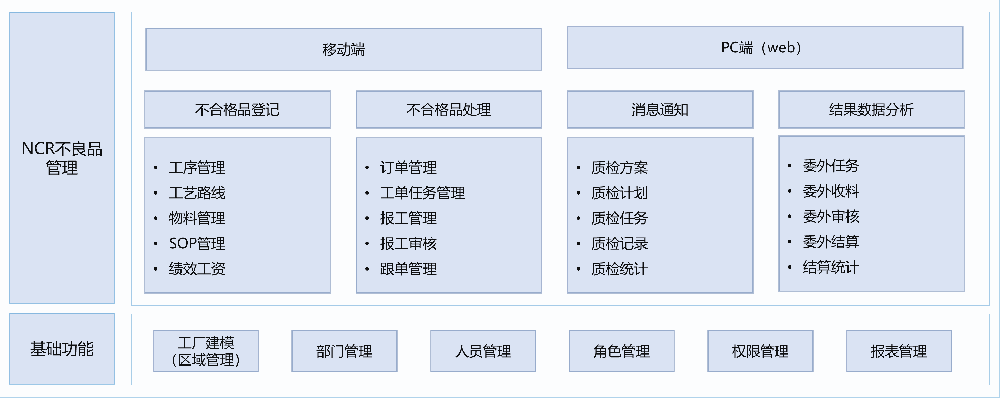

Function Introduction

Non-conformance products registration

- Quickly record and identify production processes through mobile systems

- Quickly recording and identifying non-conforming product information found in production processes through mobile device, and generate corresponding defective product lists

- The system can automatically associate suppliers with corresponding part numbers

- The system automatically generates a unique NCR number for each record.

NC label printing

- Automatically generate NC product labels through the system and print them onto the products, waiting for relevant personnel to dispose of defective products

- The label includes a QR code automatically generated by the system, relevant responsible persons can quickly identify and process it by scanning from mobile devices

Events Notification

- Automatically send messages to internal responsible persons via email

- Automatically send messages to external supplier via email

- The system can have built-in email templates, including email titles and body text

- The email attachment contains an automatically generated NCR report document

Tracking Processing

- The system can uniformly track the registration information and processing status of non-conforming products according to the non-conforming product handling process

- The system can repeatedly confirm that non-conforming products have been isolated

- The system can record changes to various states during the processing, including status, relevant explanations, etc

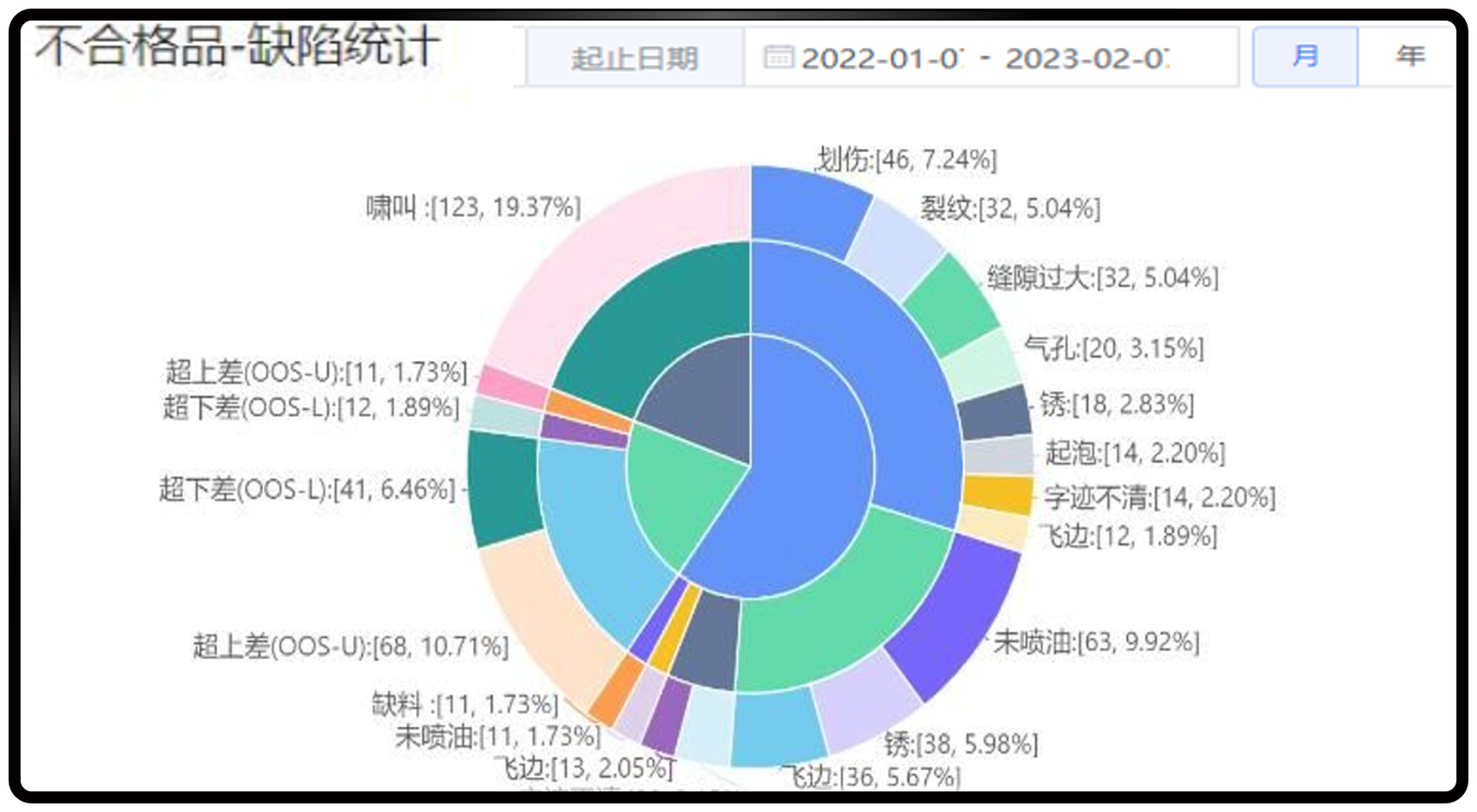

Defective products statistics

- Automatically generate reports based on registration and processing tracking data

- Statistical analysis of non-conforming products processing status

- Generate non-conforming products types’ statistics by part number

- Generate non-conforming products types’ statistics by production line

- Other customized non-conforming product statistical reports

More...

- Can interface with business systems such as MES/ERP

- Supports mobile devices and PAD

System Characteristics

- Realizing paperless office on site

- Convenient mobile devices, quick on-site entry of non-conforming product information

- Unified tracking of non-conforming registrations

- Quickly and automatically generate NC label information and print it

- QR coded tracking and handling of non-conforming products

- Convenient for quick recording of status changes

- Develop multi-dimensional quality analysis charts and reports

- Support quality management personnel in conducting quality analysis and improvement

Application Value

- Quick collection, processing, and analysis of non-conforming product data, reducing manual operation time and errors, and improving processing efficiency

- Real time monitoring of the quantity, types, and causes of non-conforming products, helping enterprises identify problems in time, avoiding the spread of non-conforming products and affecting product quality

- Collecting, storing, and analyzing a large amount of non-conforming product data to help enterprises identify the root causes of problems, optimize production processes and quality management processes

- Quickly generate non-conforming product reports and analysis results to help enterprises make quick decisions and take measures, reducing the impact on production and customers

- Assisting enterprises in tracking the source and flow of non-conforming products, quickly identify problems, and taking corrective measures