Equipment Maintenance System

ITENCloud Equipment Maintenance System is based on the concept of lean management, providing functions such as equipment information management, maintenance management, spare parts management, and knowledge and experience base and more, helping equipment management personnel establish comprehensive equipment information archives, developing spare parts information management, establish a quick response mechanism for equipment failure maintenance, developing proper plans for equipment maintenance, equipment inspections, patrol inspections, timely reminding the execution of plans, improve plan completion rate ITENCloud provides digital and mobile solutions for the operation and maintenance of production equipment, helping manufacturing enterprises improve equipment utilization and assist in lean digital transformation

Equipment Account

- Equipment assets, one account for one equipment

- Special equipment, Targeted management

- Equipment usage and maintenance records, full lifespan records.

- One QR code for one equipment, management with QR code

Equipment Management

- Daily report of equipment and operation records

- Status Changing management

- Transfer management Location changing

- Equipment inventories management

Repair Management

- Equipment malfunction, quickly scanning code for repairing

- Maintenance work order assignment

- Planned maintenance and outsourced maintenance

- Detailed records about maintenance and labor costs

Equipment and patrol inspection management

- Inspection plan and schedule

- Daily equipment inspections and periodic patrol inspections

- Records of equipment inspections and patrol inspections

- Abnormal items discovering, closed-loop management

Maintenance Management

- Maintenance standards, periodic planning

- Maintenance tasks, manual and automatic dispatch

- Maintenance records, labor costs

- Clear maintenance calendar

Spare parts management

- Spare parts and inventory records

- Spare parts requesting, tools returning

- Spare parts warehousing and outbound spare parts

- Inventory inquiring, warning, and checking management

Statistics Analysis

- MTBF, MTTR KPI reports

- Statistical analysis of equipment utilization rate

- Analysis of OEE efficiency indicators

- BI analysis and failure tracking dashboard

More...

- Examine management and maintenance experience library

- 5S examine and safety examine

- Hazard managemen

- Improving proposal management

Full lifespan management by using QR Code

One code for one equipment, small code contains rich data

Digital management of equipment assets, assigning a QR code to each equipment based on the daily management needs of the equipment. Scan the code to view equipment archives, repair and maintenance records, and related documents

Maintaining by scanning code, convenient and fast.

Equipment and patrol inspecting, maintaining, repairing, handling, learning, analyzing, just by scanning the code. Full lifespan log contains all the changes, easily tracking and analyzing

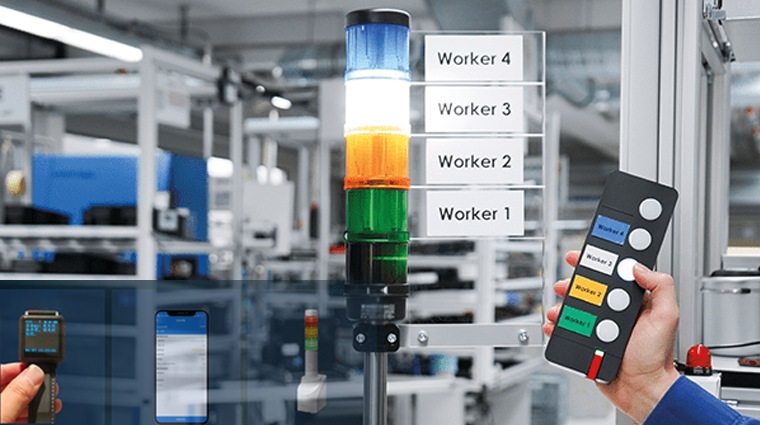

Efficiency improvement of manual workplaces

Optimize the work process, respond quickly to workstation events, and use warning lights to visualize events. At the same time, it can also expand the collection of data on workstation status (work, departure time), takt time, and other data

-

Quick response to workplace production events

-

Monitoring of worker processing, departure status, and duration collecting

-

Can achieve extended functions such as takt time collection and simple event requests

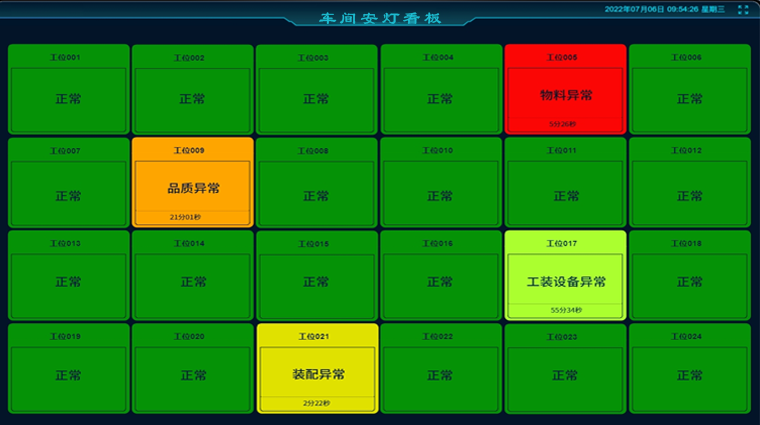

Intelligent management of production equipment

Minimalist and low-cost physical level signal acquisition, suitable for all equipment

Adopting a simple and low-cost device for collecting tri-color light signals, data can be quickly and easily collected to optimize manufacturing processes, shorten response time, and improve production efficiency.

-

Automatic reporting equipment shutdown, timely response, shortening response time, and reducing shutdown time

-

Real time online monitoring of equipment operation status, production progress, and abnormal events status, clear at a glance

-

Automatically collecting statistics data of equipment utilization rate and Overall Equipment Effectiveness

-

Automatically counting operation, faults, and waiting frequencies, analyzing waste of working hours, and provide support for improvement

Application Value

Improve event processing efficiency Reduce management costs

On site visual management Quick, intuitive, and transparent

Production event data mining and underlying problem detection

Power tool for lean management

Lightweight Lean Launching easily

Low investment cost

The system and implementation costs are significantly lower than traditional industrial management software

Quick delivery

Quick launching in 5-7 days, with short implementation time, way lower than traditional software

Zero threshold for operating

Industrial APP, simplifying complexity, friendly and easy to use

High value pay-back

Addressing the true needs of site management and easy to implement